Producing exquisite leather with quality manufacturing

Innovative technologies mixed with sustainable alternatives

Manufacturing excellence with sustainable goals

With state-of-the-art manufacturing facilities, Naser Group is equipped to deliver up to 5 million sq. ft. of finished leather, along with 2 million+ gloves, and 50,000+ garments annually. We believe in quality, innovation, and sustainability and invest in the finest manufacturing technology. This assists us in producing the finest leather, gloves, and garments.

Here’s how we manufacture our trending products:

-

Leather

-

Gloves

-

Garments

Leather

Leather

We take natural materials based on complex, interwoven collagen chains and condition them to ensure outstanding performance while retaining their original beauty.

By removing all unwanted chemicals and pollutants from the fiber structure, we stabilize the basic structure. We then treat it with sustainable color and other materials.

Our leather making skills have been perfected throughout generations over the last 40 years. We have successfully imbibed innovative science with modern machinery without losing the ancient craft. In our 40 different procedures, we work on the architecture of the collagen structure to enhance strength, longevity, softness, and other necessary properties.

Gloves

Gloves

Glove making has advanced dramatically over the last three decades as both materials and our understanding of sizing has changed. Leathers, elastics, and other components have all been developed to work better in each end-use environment, such as golf, military purposes, outdoor use, or high fashion.

By making our leather, we can create and develop materials specialized for each end-use and prioritize water resistance, grip characteristics, temperature protection, color fastness, and many more.

We produce two million leather gloves annually. Our team of experts are dedicated to putting the perfect gloves together with precision to ensure the perfect fit while retaining all the properties offered by different components.

Garments

Garments

With advancements in leather making, the garment production process has gone through enormous changes in technique and design.

Modern technology helps our skilled staff decide the perfect use of each garment piece and create garments that will wear evenly across the panels and always look good.

Our team is trained in our in-house training school to provide the intended look for every item. We pay great attention to details like types of threads and accessories so that the longevity of every article is assured.

The designs and size patterning is worked in with our customers or by our experts to ensure well-fitting contemporary looks for all the items coming from our studio.

All our manufacturing processes are conducted under strict, onsite supervision to ensure the maintenance of our safety measures. We care for the environment and hence, incorporate sustainable practices in our processes.

Transforming the world of leather, one product at a time

- Tanning Technology

- Performance Technology

Tanning Technology

Dry Tan

Dry Tanning is a revolutionary water saving tanning system that brings a paradigm shift in leather manufacturing sectors. It uses an eco-friendly range of products as a medium for tanning instead of water, drastically reducing water consumption. In addition to being a green initiative, it also results in significant time savings. For more information, please visit www.nsecosolution.com.

Naturtan

The vegetable leathers are treated with environmental friendly natural vegetable tannins like polyphenols from cashew nut shells and olive oil wastewater. The leathers tanned with vegetable tannins substantially improve their natural character and durability, making the leather more natural, soft, and supple. This is long-lasting with slight darkening and creates an individual patina, making each product unique.

The leathers are tanned with a water conserving process, saving 30% water compared to the conventional process.

Blancatan

This is our new line of leathers developed with a combination of synthetic-based chemistry. This system is environmentally sustainable and eliminates the use of chromium and heavy metals, thereby creating lightweight leathers with good color brilliance and softness, comparable to chrome-tanned leather. This process can be applied to all types of leather.

Performance Technology

Griplex

Griplex provides performance benefits in sporting and functional gloves without losing any of the softness or natural feel of the original leather. Our unique process causes the structure to soften, increasing surface area, and consequently improving grip.

Aromatiq

Using three captivating fragrances, Aromatiq is made to elevate the experience and bring a more luxurious feel to our leather.

Supreme Leather

This is our new line of next-generation performance leather. Using specially crafted technology, we enhance abrasion, further extending the life of our leather.

Aloe Vera Leather

Originally created for golf gloves, our aloe vera leather is made with our patented technology that enhances leather lubrication. This helps us enhance the grip of our leather gloves for all weather conditions, ensuring long-lasting performance.

Providing the luxury of

premium leather, worldwide

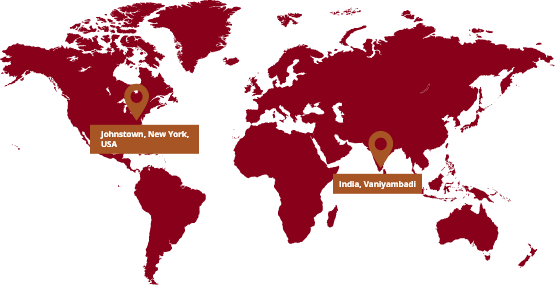

As part of our commitment to improving customer service and experience, Naser Group is delighted to provide distribution services for our products (currently only in North America) to assist brands in delivering goods directly to their retail stores.

Our current distribution locations are as follows:

We will continue to add locations in the future as suitable growth opportunities come our way. Our network of excellent logistics partners for sea/air shipments and courier services can support delivering goods to any location on the planet.

Other services

Along with our revolutionary leather products and innovative technology, we also offer an array of services such as:

To meet the needs of our customers, we have an excellent sourcing network.

We have in-house designers who can assist customers in creating new designs using leather, textiles, and other materials sourced from around the world.

As part of our customer service, we can not only grade patterns for sizes, but also create them from sketches and measurement charts for women, men, and children.

We provide sample making services to assist customers in obtaining approval for design and size, assisting sales, and increasing their confidence in placing orders for production.